sources of error in hardness testing|hardness calibration requirements : distributor Failure to properly prepare and execute a Rockwell hardness test can result in compromised test data or false readings, potentially contributing to the production and delivery of substandard .

WEB308 Market St SE, Roanoke, VA 24011. At ALCOVA, we offer a convenient online application that simplifies the mortgage process. Just answer a few questions and easily sync your financial info!

{plog:ftitle_list}

677 garotas de programa em São Vicente (SP) agora diponív.

1. Test piece 2. Hardness testing machine 3. Environment 4. Operator 2.0.3 The table lists more than 20 sources of uncertainty which may all contribute significantly to the total uncertainty of . Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors. The .Step 1- Identifying the parameters for which uncertainty is to be estimated Step 2- Identifying all sources of uncertainty in the test Step 3- Classifying the uncertainty according to Type A or B . Abstract. In the use of hardness test blocks, the uncertainty due to block non-uniformity can be reduced if one is willing to make measurements at specified locations on the .

The sources of error to be discussed are: (1) the hardness machine’s lack of repeatability; (2) the non-uniformity in hardness of the material under test; (3) the hardness machine’s lack of .Failure to properly prepare and execute a Rockwell hardness test can result in compromised test data or false readings, potentially contributing to the production and delivery of substandard .

In order to reduce the testing errors in Rockwell hardness of metal specimens and improve the accuracy of hardness testing, several methods had been tried out and examined . In order to reduce the testing errors in Rockwell hardness of metal specimens and improve the accuracy of hardness testing, several methods had been tried out and examined based on GB/T.

The Rockwell hardness test continues to be applied as a tool for assessing the properties of a product while the tolerances on the acceptable material hardness have become tighter and .The water chemistry If you've just treated the water, wait to retest until the proper amount of time has elapsed (as specified by the treatment chemical manufacturer, typically at least one but usually two complete filtration cycles).These hardness testing methods are useful tools in determining shallow layer hardness such as coating hardness, case depth and surface hardness. Furthermore, selective testing of specific grains or constituents cannot be .

4.2 Low-Energy Components in the Spectrum— Some of the primary Co-60 gamma rays (1.17 and 1.33 MeV) produce lower energy photons by Compton scattering within the Co-60 source structure, within materials that lie between the source and the device under test, and within materials that lie beyond the device but contribute to backscattering. As a result of .Practice of Micro Flexible Rolling. Zhengyi Jiang, . Haibo Xie, in Microforming Technology, 2017. 15.2.3.2 Hardness Test. A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N with a dwelling time of 12 s. Hardness measurements were . Based on measurements of hardness, the scientists were able to estimate YS and UTS of different metals and alloys. Consequently, it became possible to dispense with the expensive tensile tests .

As decided in the last EA/LC Meeting in Berna, a new Examples on “ Estimation of the Uncertainty of the Brinell and the Vickers measuring method” was prepared until the end of June 2002 by Dr .About Taylor. There’s a Reason Taylor Is the Most Trusted Name in Water Testing. In fact, there are a number of reasons. Taylor is a leading developer and manufacturer of water-testing kits and reagents for the pool/spa and industrial sectors.

The Rockwell hardness test continues to be applied as a tool for assessing . calibrations is a beneficial step to reducing measurement errors. The purpose . Sources of uncertainty for the certified average HRC hardness value with hypothetical values to be used

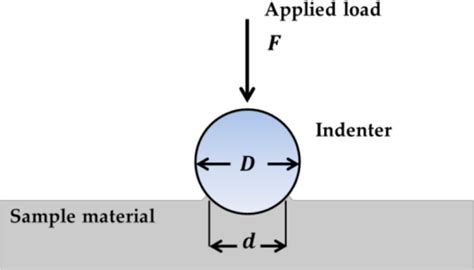

To simplify the uncertainty calculations it is advisable o regroup the significant sources t affecting the tensile testing results in Table 2 in the following categories: • Uncertainty due to errors in the measurement of cross-sectional area • Uncertainty due to errors in the force measurement There are many methods for hardness testing, each with different principles, leading to different hardness values and meanings. The most common is the static load indentation hardness test, such as Brinell Hardness (HB), Rockwell Hardness (HRA, HRB, HRC), and Vickers Hardness (HV). The application of the theory of errors, in addition to the dispersion of results, allows the evaluation of other sources of errors [11,12,13,14,15,16]. . 2.1 Data Analysis of Vickers Hardness Test. One hundred indentations were performed in a single specimen with dimensions (length x width x thickness) 20 mm x 20 mm x 4 mm, using a Vickers .

uncertainty in hardness testing machine

This class presents a description of each hardness testing method, along with discussions on how to choose and perform a test, how to read hardness ratings, and how to prevent common errors. Hardness tests ensure that raw, in-process, and finished materials have the correct mechanical properties.

A good test engineer must have an excellent understand-ing of the sources of errors that may be introduced during a test. Before commencing testing, the test engineer should review the choice of sensors and measurement instruments keeping in mind the suitability and accuracy of each. In order to make accurate measurements, in other words, one As water hardness is usually reported in terms of mg/L of calcium carbonate (even if water contains both calcium and magnesium), we will use for calculations slightly strange reaction equation: . sources of errors. In general this is a simple titration, with no other problems then those listed as general sources of titration errors. The most .BRINELL HARDNESS TESTING The Brinell hardness test is used for larger samples in materials with a coarse or inhomogeneous grain structure. This page describes the Brinell hardness test in detail and gives you practical .

These sources of errors in lab should be studied well before any further action. So, what are the particular sources of each error? The reliability of physical and chemical testing has been significantly impaired; by equipment, samples, .

When testing large samples of test material or material with a long shape that significantly overhangs the hardness machine's anvil support, the material should be additionally supported using . Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learrn more about hardness testing basics here. The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. What does hbhbw mean on Brinell test?Numerous aspects of the Rockwell hardness test can influence the measurement result. These include the function and calibration of individual components of the hardness machine, variations in the indenter, the testing cycle that is used, the testing environment, the condition of the test material, and the operator. When considering all of these influences, it seems remarkable that .The water chemistry If you've just treated the water, wait to retest until the proper amount of time has elapsed (as specified by the treatment chemical manufacturer, typically at least one but usually two complete filtration cycles).

The most influential sources of high uncertainty in the determination of the elastic modulus of metallic materials via tensile testing are test system (dimension measurement device, gauge determination system, extensometer type, alignment system, test machine stiffness, force measurement accuracy, extensometer accuracy) and test procedure .Brinell tests have long been the preferred method of assaying the hardness of metals during forming operations. The general significance of the test has been codified in empirical laws, especially those of Meyer, O’Neill and Tabor. On the other hand, the .

established microindentation-hardness test methods. Ref erences have been provided for those readers requiring more information in specific areas. SELECTING A MICROINDENTATION HARDNESS TEST METHOD In a laboratory where more than one option for microin dentation hardness testing is available, the choice of

Rockwell hardness values are expressed as a combination of a hardness number and a scale symbol representing the indenter and the minor and major loads. The hardness number is expressed by the symbol HR and the scale designation. The most common indenter type is a diamond cone ground at 120 degrees for testing hardened steels and carbides.A method for predicting the ultimate tensile strength (S u ) of a material from Brinell-type hardness tests is described for several metals including steel, aluminum, and copper alloys. The prediction of S u is based on a consistent relationship between S u and a material’s hardness coefficient, K d . A simple experimental procedure for determining K d from indentation .

uncertainty in hardness testing

Q: heat -treatment: a-Draw on the same graph paper the (Hardness- Distance from quenched end) curve for. A: Vicker's Hardness Test: The Vickers hardness test is a test performed to quantify the hardness of.

The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .

Resultado da 2 dias atrás · win11使用360软件小助手无法开机自启动win11使用360软件小助手无法开机自启动,每次开机都要自己点开,请问有没办法解决 请使用手机微信扫码安全登录 切换账号密码登录 绑定手机号 应国家法规对于账号实名的要求,请您在进行下一步操作前 .

sources of error in hardness testing|hardness calibration requirements